Your Ultimate Resource for Spray Dryer Knowledge and Solutions

Explore expert insights, industry trends, and innovative solutions in spray drying technology.

Get Solution

Tailored Solutions

Custom designs and turnkey plant solutions for your needs.

Proven Expertise

Over 800 successful installations across industries.

Certified Quality

ISO 9001:2015 certified for highest industry standards.

Leading the Way in Spray Dryer Expertise

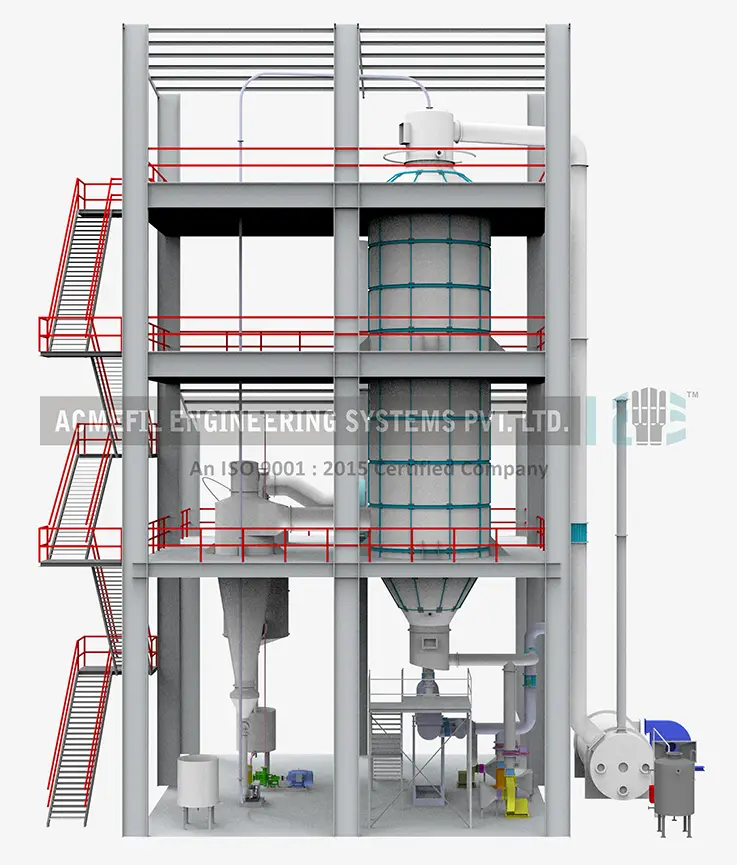

Acmefil Engineering Systems Pvt. Ltd. is not just a leading spray dryer manufacturer; we are pioneers in the field, dedicated to innovation and excellence in spray drying technology. With over 25 years of experience, we understand the unique challenges faced by industries ranging from pharmaceuticals and food processing to chemicals and ceramics. Our expertise lies in delivering customized spray drying solutions that not only meet but exceed your specific needs.

Are you struggling with inconsistent product quality or facing challenges in optimizing your spray drying processes? At Acmefil Engineering Systems Pvt. Ltd., we specialize in solving these pain points. Our advanced spray dryer designs ensure uniform particle size, improved product consistency, and maximum efficiency, reducing operational costs and enhancing overall productivity. Whether you’re dealing with heat-sensitive materials or complex formulations, our team of experts works closely with you to develop tailored solutions that deliver exceptional results.

Explore our knowledge hub to gain insights into the latest trends in spray drying, learn about the different types of spray dryers, and discover how our innovative technologies can help you overcome your most pressing challenges. By choosing Acmefil Engineering Systems Pvt. Ltd., you are partnering with a company committed to driving your success through superior spray drying solutions.

Spray Dryer Applications

Chemical Industry Applications

- Polymers – Drying liquid polymers into powdered form.

- Resins – Producing resins in powder form for adhesives and coatings.

- Catalysts – Creating powdered catalysts for industrial processes.

- Detergents – Manufacturing powdered detergents and surfactants.

- Pesticides – Drying pesticides for stable, easy-to-handle powders.

- Herbicides – Producing herbicide powders for agricultural use.

- Fungicides – Spray drying fungicides for consistent application.

- Insecticides – Creating powdered insecticides for controlled use.

- Dyestuffs – Producing powdered dyes for textiles and industrial applications.

- Pigments – Manufacturing pigments for paints, coatings, and inks.

- Fertilizers – Producing powdered fertilizers for agriculture.

- Inorganic Chemicals – Drying inorganic compounds like salts and oxides.

- Organic Chemicals – Spray drying organic chemicals for various industrial uses.

- Spray Absorption (Flue Gas Desulfurization – FGD) – Removing pollutants from flue gases.

- Spray Concentration – Concentrating chemicals through controlled drying.

- Spray Reaction – Facilitating chemical reactions through spray drying.

Ceramics Industry Applications

- Ceramic Powders – Producing fine ceramic powders for tiles and porcelains.

- Glazes and Enamels – Spray drying glazes for consistent application on ceramics.

- Refractory Materials – Drying refractory materials used in high-temperature environments.

- Advanced Ceramics – Producing powders for technical and advanced ceramics.

Pharmaceutical Industry Applications

- Active Pharmaceutical Ingredients (APIs) – Drying APIs for precise dosing.

- Vaccines – Spray drying vaccines for stability and shelf life.

- Antibiotics – Producing powdered antibiotics for oral or injectable forms.

- Enzymes – Drying enzymes used in pharmaceuticals.

- Nutraceuticals – Producing dietary supplements in powder form.

- Herbal Extracts – Drying herbal extracts for pharmaceutical use.

- Blood Hemoglobin – Processing hemoglobin into powder for medical use.

Food and Beverage Industry Applications

- Milk Powder – Producing milk powder for extended shelf life.

- Whey Protein – Spray drying whey for supplements and food products.

- Egg Powder – Drying eggs for baking and food manufacturing.

- Instant Coffee – Producing instant coffee granules.

- Tea Powders – Creating powdered tea for instant beverages.

- Flavors – Drying liquid flavors into powder form for consistent application.

- Spices – Producing powdered spices for culinary use.

- Fruits and Vegetables – Spray drying fruits and vegetables into powders.

- Carbohydrates – Producing starches and sugars in powder form.

- Oleoresins – Drying oleoresins used in food flavoring and coloring.

Agriculture and Animal Feed Industry Applications

- Animal Feed – Producing powdered animal feed additives.

- Vitamins and Minerals – Spray drying supplements for livestock.

- Fish Products – Drying fish extracts for animal feed.

Textile Industry Applications

- Reactive Dyes – Producing powdered dyes for textile dyeing processes.

- Optical Brighteners – Creating brighteners for enhancing fabric appearance.

Cosmetics and Personal Care Industry Applications

- Cosmetic Powders – Spray drying active ingredients for cosmetics.

- Fragrances – Producing powdered fragrances for personal care products.

Environmental and Energy Industry Applications

- Biofuels – Spray drying biomass and algae for biofuel production.

- Spray Absorption (Air Pollution Control) – Removing pollutants from emissions.

- Water Treatment – Producing chemicals like Poly Aluminium Chloride (PAC) for water treatment.

Other Industrial Applications

- Glass Products – Producing powdered glass for various industrial uses.

- Paper and Pulp – Drying additives used in paper manufacturing.

- Paints and Coatings – Producing powdered pigments and additives for paint formulations.

Our Spray Dryer Clients

Why Choose Us

ACME – as the meaning is – ‘THE HIGHEST POINT OF PERFECTION’ and Acmefil today strives to fill in the gap between the PRESENT & ACME.

- 24+ years of industrial experience

- ISO 9001:2015 Certified Company

- Latest and Most Advanced Manufacturing Technology

- 20 + Engineers After Sales Services, Installations, and Commissioning Team

- OEM Spare Parts and Maintenance Contract